Benefits of Zirconium Beads

Zirconia beads are spherical particulate materials that may be used for coatings. Its function is to lessen fees, grow solids content, offer overall performance, and enhance process working conditions. The following zirconia bead producer benefits it has.

-

Hard and wear-resistant

The zirconium beads manufacturer have excessive hardness and put on resistance, making the paint floor difficult and scratch-resistant. Surfaces final like new, saving you the fee and time of maintenance and repainting. Soft or irregular particles can be put on away speedy or crack the surface if conventional fillers are used.

-

Gloss manage

Many glosses manage materials’ growth viscosity. However, using zirconium beads can significantly lessen gloss without increasing viscosity.

-

Reduce viscosity and growth flow.

Compared to various irregularly shaped packing’s, zirconium balls roll between bearings just as easily as steel balls. Zirconium beads have a special gravity, are clear to roll, and have great kinetic power, thus reducing the stickiness of the formulation, increasing the flow, and improving the ability to play.

-

Less put on and tear of equipment

Zirconium beads are introduced for the duration of production and grinding because of their high compressive strength. To enhance the dispersion effect, sand grinding, ball milling and rolling may be used. The use of zirconium beads reasons much less put on the equipment than the use of different filters of equal or decrease hardness.

-

Effective barriers

Dense, difficult, abrasion-resistant, and inert particles make the system extremely durable and occasional-permeability, forming a powerful barrier against harsh climate and chemical attacks.

-

Stability

Due to its composition of inert ceramics, zirconium beads are proof against assault by various chemicals.

-

Large filling volume and low fee

Compared to different formed fillers, zirconium beads have a completely small floor place to volume ratio. It can lessen the quantity of resin and growth the quantity of filler, and the smaller extent of microspheres fills the voids among the bigger volume of microspheres, which will increase the stable content, reduces the VOC, and decreases the fee.

-

Radiation curing

Zirconium beads are obvious to ultraviolet rays below 25nm, and the ultraviolet power can penetrate the whole coating, which is helpful for the deep curing of ultraviolet curing coatings and improves the construction efficiency. For electron beam cured coating applications, zirconium beads can grow viscosity and manage the flow.

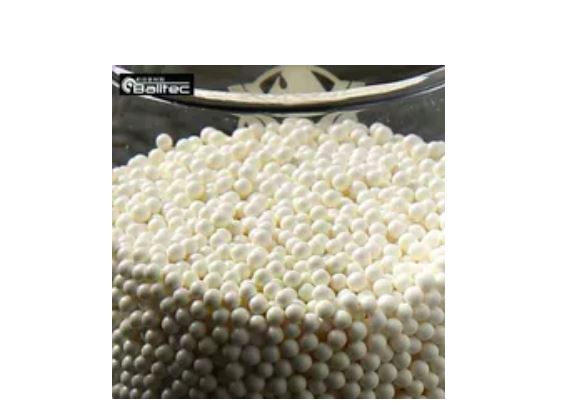

What are zirconium beads

Zirconium beads are a kind of beads made from zirconium. They are regularly utilized in earrings due to their excessively excellent general and bright colors.

Zirconium beads are tiny, lightweight beads made from the uncommon earth mineral zirconium. They have plenty of programs which include aerospace, automotive, military, and healthcare markets.

The aluminum fuselage of the plane became too heavy, so zirconium beads had been used rather than steel in the fuselage. They additionally improve the aircraft frame, affecting the aircraft’s overall performance and pilot safety.

In the healthcare industry, zirconium beads are utilized in dental implants, cardiac stents, and different scientific devices. They also are used to increase the existence of cell phones, laptop monitors, and different digital devices.