How to Overhead Line Stringing Tools the Right Way

Your joist, post and compression connection are all important components of overhead line stringing, but they’re just the tip of the iceberg. The right overhead line stringing tools can make the process much easier and more productive. Read on to discover how to choose the right overhead line stringing tool for your specific application.

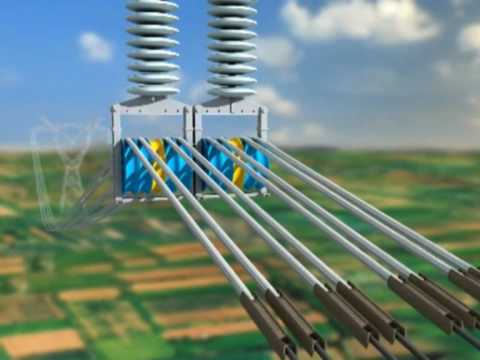

What is overhead line stringing?

Overhead line stringing is the process of connecting overhead cables between poles or between joists. When overhead lines are run through populated areas, they are usually in a steel or aluminum raceway. The raceway is stretched between two metallic posts that are connected to a Transmission Core or a Structure Core. These posts are then connected to the ground. In this type of installation, there is no need to turn the post into a socket as is done with a traditional post-and-girth.

Why Should You Use Overhead Line Stringing?

If you’re running overhead lines, it’s crucial that you know how to string them. If you can’t figure out how to string the overhead lines correctly, you might have a hard time running the electrical grid. This is especially true if the overhead lines are long and the area is relatively wide. With no electricity, you’d have a hard time finding emergency services. Overhead line strings also make good fiber optic cables because they have less capacitance than underground cable runs. This means that fiber optic lines can be run in overhead lines with little impact on your electrical service.

Types of Overhead Line Stringing Tools

There are many different types of overhead line stringing tools. Here are a few of the most common: Rack and Pinion Setups – These are the least expensive and most common overhead line stringing tool. They consist of one or more aluminum or steel pinions. The length and spacing of the pins determine the tension in the overhead line. Rigid – This overhead line stringing tool is the most expensive, weighing up to 40 tons. It is used for high tension overhead lines with extremely hard NBC-free Poles. It consists of a rigid steel pole with a reinforcement bar running the length of the pole. The bar is connected to the end of the pole using a coupler. Overhead Lumber – This is used when there isn’t enough room to use a Rigid or a Pole System. It consists of four 2’x4’ planks connected side-by-side with 1/4” twist-minstering. It is often used in warehouses and other large applications where space is limited.

Final Words

Overhead line stringing is a skill that can be developed and practiced. With the right equipment, you can reduce the time it takes to string overhead lines by up to 50%. This means more time spent on what’s really important—running your business!